News & Events

WEICHAI AMERICA

At 9:00 am on January 8, 2022, Weichai Power released the world’s first diesel engine with a base engine thermal efficiency of 51.09% and major achievements in hydrogen technology achievements.

Tan Xuguang, Chairman of Shandong Heavy Industry Group, Chairman of Weichai Power and Director of the Academic Committee of the National Fuel Cell Technology Innovation Center, reported the research findings of the world’s first diesel engine with a base engine thermal efficiency of 51.09% developed by Weichai Power, the operation of the National Fuel Cell Technology Innovation Center and the “Hydrogen for Every Home” technology demonstration project. TüV SüD, an world-renowned test authority, issued a certificate of thermal efficiency of 51.09% to Weichai Power. Then the delivery ceremony of hydrogen-powered heavy-duty truck delivery for demonstrative operation between Shandong Heavy Industry and Shandong Port was held.

FISITA, MIT, AVL, FEV, SwRI, Bosch Group and Vitesco Technology, as well as the China Mechanical Engineering Society, the China Automotive Engineering Society, the China Internal Combustion Engine Society and the China Internal Combustion Engine Industry Associations extended congratulations on the release of the diesel engine by message or video link.

Challenging Limits

Scaling New Heights

Today when green and low carbon development has become a global consensus, China has set the strategic goal of achieving carbon peak by 2030 and carbon neutralization by 2060. Transportation is an important field for this target, and the internal combustion engine industry plays an important role in this process.

Thermal efficiency is the yardstick for the fuel efficiency of internal combustion engines: higher thermal efficiency represents lower fuel consumption and better effects of energy conservation and emission reduction. It is also a reflection of a country’s technical strength in diesel engines. Improving thermal efficiency has been the common pursuit of the global diesel engine industry since diesel engines emerged 125 years ago. Weichai Power released the world’s first commercial diesel engine with a base engine thermal efficiency of 50.23% in Jinan on September 16, 2020, establishing a new thermal efficiency benchmark for global diesel engines, just like the first time in human history that a 100-meter sprint was completed in 10 seconds. Just 480 days later, Weichai set a new world record by increasing the base thermal efficiency to 51.09% just as a 100-meter race was completed in 9 seconds, further enhancing China’s significance in the global internal combustion engine industry.

The base engine thermal efficiency of 51.09% is another significant revolution of traditional engines, as well as a technical preparation for the implementation of the “China VII” emission standard. The application of this technology will help Weichai Power lead the world in a full spectrum of diesel engines, be of great strategic significance to promoting the energy-efficient and green development of China’s traditional internal combustion engine industry, and play a significant leading role in the global internal combustion engine industry.

According to estimation, compared with existing key products (diesel engines with thermal efficiency of 46%) on the market, those with a thermal efficiency of 51% can lead to a reduction of 10% in fuel consumption and carbon dioxide emissions alike, saving fuel consumption by 16 million tons and costs by approximately 140 billion yuan annually, and reducing carbon dioxide emissions by 50 million tons annually. With the massive use of the top technology in the industry, it will generate huge economic and social benefits.

Hydrogen-powered Future

While promoting the innovative and low-carbon development of traditional engines, Weichai Power has taken the new energy industry as an important strategy. The first batch of Sinotruk hydrogen-powered heavy-duty tractor trucks with Weichai’s high-power hydrogen fuel cell systems are powerful, eco-friendly, safe, reliable and efficient for full-time use.

In 2021, the National Hydrogen Cell Technology Innovation Center, the only of its kind in China, was established under the initiative of Weichai Power. Meanwhile, the Ministry of Science and Technology (MOST) and Shandong entered into a framework agreement on the “Hydrogen for Every Home” technology demonstration project. Based on the center, the ministry has carried out multi-scenario demonstrative application of hydrogen energy in Shandong, and sped up breakthroughs in key hydrogen technologies and the development of the hydrogen industry, thereby creating a duplicable Shandong sample for the hydrogen industry.

Since the launch of the “Hydrogen for Every Home” technology demonstration project, with the strong support of MOST and Shandong, the National Hydrogen Cell Technology Innovation Center has established an innovation consortium centered on Weichai Power and constituted by enterprises, universities and research institutes, to accelerate technical breakthroughs and industrialization, and successfully develop 15-200kW hydrogen fuel cell systems. The company’s 200kW fuel cell systems were selected for the National Exhibition on Sci-tech Achievements in the “13th Five-Year” Period in October 2021. The company was the first to conduct an environmental adaptability test of fuel cell vehicles in extreme cold, achieving one-time successful start-up at a temperature of 34 degrees Celsius below zero. The company was the first in the industry to turn out products lasting 30,000 hours, pioneering the industrialization of Chinese fuel cells.

Based on its highly reliable fuel cell products, Weichai Power has carried out multi-scenario demonstrative application. In terms of hydrogen-powered parks, the company’s first large-power container-type hydrogen fuel cell heating and power generation system and 30kW solid oxide fuel cell heating and power system, both the first of its kind in China, were put into operation in Weifang; the company developed China’s first 3t hydrogen fuel cell forklift, creating a zero-carbon-emission logistics handling environment. In terms of hydrogen-powered ports, China’s first 80-seat hydrogen fuel cell passenger ship developed by the company was tested successfully with zero carbon emission in the Xueye Lake, Jinan; and the company launched China’s first hydrogen fuel cell heavy-duty truck demonstration project at Qingdao Port. In terms of hydrogen-powered highways, China’s first highway hydrogen fueling station constructed by the company went into operation; a 49t fuel cell heavy-duty truck powered by Weichai operated for more than 5,000 kilometers from Taishan Steel, Jinan to Dongjiakou Area of Qingdao Port. On October 27, 2021, a Chinese original, world leading and fully-homemade Sinotruk Huanghe ski-waxing truck with a Weichai 162kW hydrogen fuel cell system was delivered for use during the Winter Olympic Games Beijing 2022. On January 4, General Secretary Xi Jinping inspected the ski-waxing truck. A series of outcomes marks that the “Hydrogen for Every Home” technology demonstration project is turning from blueprint into reality.

Tan said the base engine thermal efficiency of the internal combustion engines being up to 51.09%, massive application of new energy in products, and the “dual driving force” strategy, have kept Weichai Power ahead in the development of traditional high-end engines and new energy engines, and opened up a new path for diversified energy transformation under the national strategy of carbon peak and carbon neutralization.

China’s Weichai Group has officially launched the first commercial, heavy-duty high-speed diesel engine in the world to have a brake thermal efficiency (BTE) above 50%

During a launch ceremony held in China earlier today, Germany’s TÜV SÜD and the China Automotive Technology and Research Center—the country’s national internal combustion engine testing organization—awarded Weichai certificates for BTE of 50.26%. The engine was jointly unveiled by Ling Wen, vice governor of Shandong Province and academician of the Chinese Academy of Engineering; and Tan Xuguang, chairman of Shandong Heavy Industry Group and Weichai Group.

Since the development of the first diesel engine in 1897, the engine’s brake thermal efficiency increased from 26% to 46%, where it remained until now, according to Weichai. To further improve the diesel engine BTE, Weichai drew on its 70 years of experience in the internal combustion engine R&D. For the past 10 years, the company invested $4.4 billion USD in diesel engine development.

Since 2015, Weichai’s special technical research team has conducted a large number of simulations and bench tests to improve the efficiency of its engines, eventually leading to this historic breakthrough, the company said. Weichai credits the high brake thermal efficiency rate to five proprietary technologies: advanced fields synergy combustion technology, harmonious design technology, exhaust energy distribution technology, subzone lubrication technology, and WISE control technology:

- Weichai’s fields synergy combustion technology optimizes the design of the air passage, fuel injection, combustion chamber profile and other systems to make the relationship between the velocity field and concentration field in the combustion chamber more harmonious, increasing combustion speed by 30%.

- Harmonious design technology enables the diesel engine body’s to withstand high peak firing pressure (PFP), which greatly limits combustion improvement, by about 60%. The technology also strengthens the engine’s overall structure.

- The company’s exhaust energy distribution technology, developed in response to the increased difficulty of emission control caused by improved combustion, pioneered reconstruction of the exhaust system design. The technology adapts to the demand for exhaust gas recirculation while ensuring the efficiency of turbines, meeting regulations and standards, and achieving 1% increase in brake thermal efficiency.

- Subzone lubrication technology, developed based on the different characteristics of the friction pairs of the system, uses several friction reduction technologies to reduce the overall friction by 20%.

- WISE control technology takes advantage of Weichai's self-developed ECU by developing a series of more precise control predictive models, making every part of the diesel engine more efficient.

Weichai’s achievement is a historical moment in the development of internal combustion engines, the company said. Several diesel engine experts including Bosch, AVL, FEV, SAE, China Machinery Industry Federation, China Internal Combustion Engine Industry Association, and China-SAE congratulated Weichai on this breakthrough and praised the company for setting a new benchmark for the diesel engine BTE.

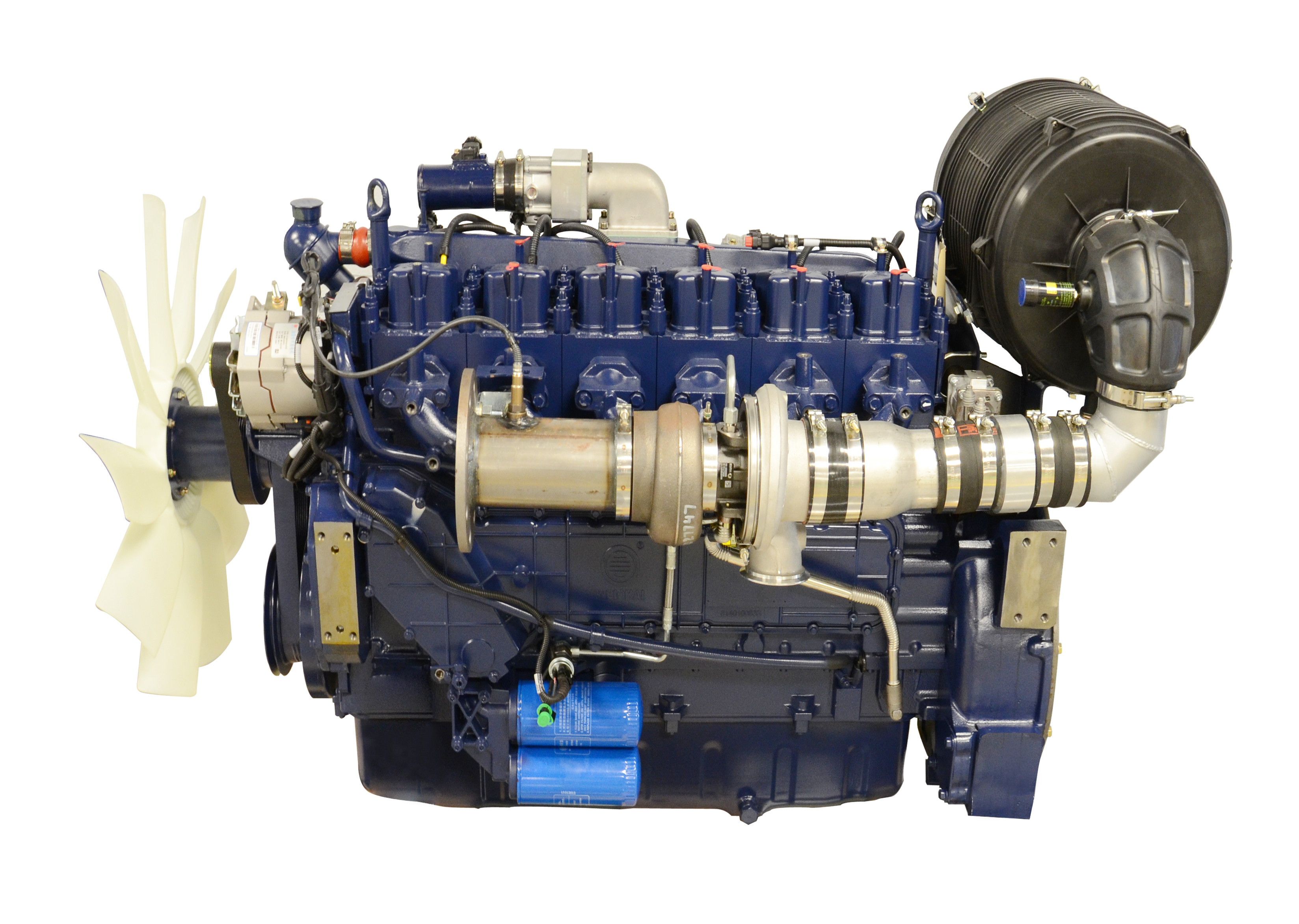

The Weichai 50% BTE engine has a 13 L displacement, is rated at 560 hp at 1900 rpm, and utilizes a 2500 bar fuel injection system. The engine meets China VI/Euro VI emission requirements. Increasing brake thermal efficiency from 46 to 50% reduces diesel fuel consumption and CO2 emissions by 8%.

Weichai said it has received strong support from Bosch Group and other global suppliers and R&D consulting firms in the development of this program. Weichai’s future plans include partnering with more global companies to move toward a goal of 55% thermal efficiency, Chairman Tan Xuguang announced during the today’s ceremony.

The collaboration between PSI and Weichai deepened in late April 2019, when Weichai increased its ownership of PSI’s common stock to 51 percent. The increased investment reflects the ongoing success of the partnership and Weichai’s confidence in PSI. Weichai has a long track record of improving the sales, operations and technology of the companies it invests in while keeping the executive and operational staffs in those companies intact.

“People have asked me what changes will be made after Weichai becomes a 51 percent owner of PSI, and I have told them there is only one change – Weichai will give more support to PSI,” said Dr. Shaojun Sun, chairman of the board of PSI and director of Weichai Group Holdings Limited.

Weichai America invests $60 million, accounted for 41% of shares, in Power Solutions International (PSI), making Weichai America the largest shareholder of PSI.

Power Solutions International, (Nasdaq:PSIX) is a leader in the design, engineer and manufacture of emissions-certified, alternative-fuel power systems. The two companies have also agreed to a strategic collaboration agreement under which they will work together to accelerate market penetration opportunities for each company’s respective product lines across various geographic markets and end user segments. Through the alliance, PSI will gain access to Weichai’s international manufacturing facilities and supply chain network.

Shaojun Sun, executive president of Weichai commented, "Our strategic investment into PSI will further enhance Weichai’s globalization strategy and brand recognition by strengthening our presence in the key North American markets. Our collaboration with PSI will create synergies particularly in the areas of product manufacturing, sales and marketing and cost reduction by leveraging the experience, expertise and resources of Weichai and PSI, and will lay a solid foundation for PSI’s future growth in the Chinese and other new markets."

Weichai America have successfully finished the first production-line testing in Sacramento, CA. This is the first production-line testing in Weichai America by randomly selecting the engines from the production-line based on the projected volume and testing them in a third party lab. The emissions data are very close to those tested in the certification test thanks to all the efforts from different departments.

This is the first time of the rich-burn engine families for North American application. The nonemergency family will allow a wide range of fuel operation from 700 to 2362 BTU/CF of LHV, covering commercial pipeline natural gas, LPG, and most of the wellhead gas in oil and gas filed.

Weichai America is proud to offer the North American market a durable, reliable, clean burning, competitively priced alternative for nonroad and stationary applications. We encourage you to learn more about the Company and products on this website (www.WeichaiAmerica.com).

Come and see us at Booth 1604

Come and see us at Booth 7616

Weichai America is pleased to announce that it has received EPA certification on the first of its family of Natural Gas off-road engines for North American application. The engineers at Weichai America’s North American headquarters in Rolling Meadows, IL have been working to utilize commercial heavy duty diesel-based products, with emissions technology from local well-known and proven suppliers. Weichai America is excited to have the WP10NG, 10L Natural Gas engine, officially launched with EPA certification, and proud to offer the North American market a durable, reliable, clean burning, competitively priced alternative for off road applications. The first certifications are for Emergency/Standby Applications rated at 225 kW, and Non-Emergency/Primary power rated at 175 kW. As the first of the planned FULL LINE OF NG ENGINES, we encourage you to learn more about the Company and products on this website (www.WeichaiAmerica.com) and/or in the recent article on Diesel Progress’s website which can be found using this link